Table of Context

- What is 3D printing?

- How does SLS work?

- What first project would I want to work on?

- Micronics

What is 3D printing?

It's a form of additive manufacturing, which is a way to create 3D objects by essentially printing them layer by layer. Formlabs products enable customers to use polymer materials to design their objects. There are other 3D printing companies that focus on different materials, such as metals for example. I remember doing an interview like 2 years back at a different 3D printing company called Desktop Metal where they focused on metals, pretty self explanatory! I also didn't get in.

Their tech focuses on two methods, SLA (stereolithography) and SLS (selective laser sintering). SLA creates the prints by using resins cured by UV light and are generally used for prints that want smoother surfaces and high resolution. First things and industries that come to mind are dental, medical, jewelry,etc. Honestly I did not dive deep into SLA materials as I was watching a webinar on SLA materials(Formlabs' Diverse SLA Materials Overview), and half way through I realized the interviewer works on the SLS side, and the end use case for this seemed much more interest0ing(business oriented like manufacturing, prototyping rather than hobbyist) so I decided to dive deep into SLS instead. It would be kind of tragicomic if the interview revolves around SLA. Fingers crossed

How does SLS work?

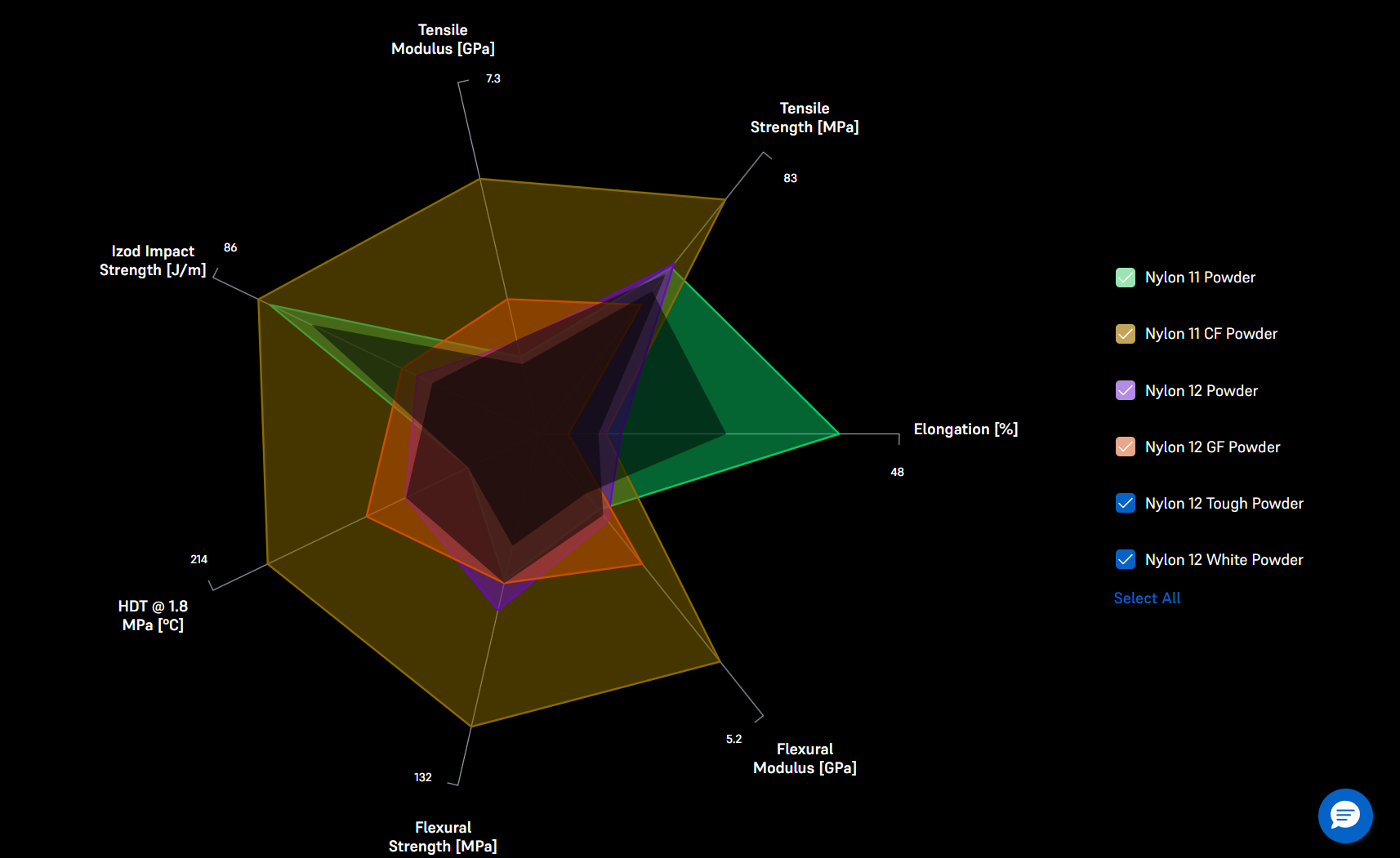

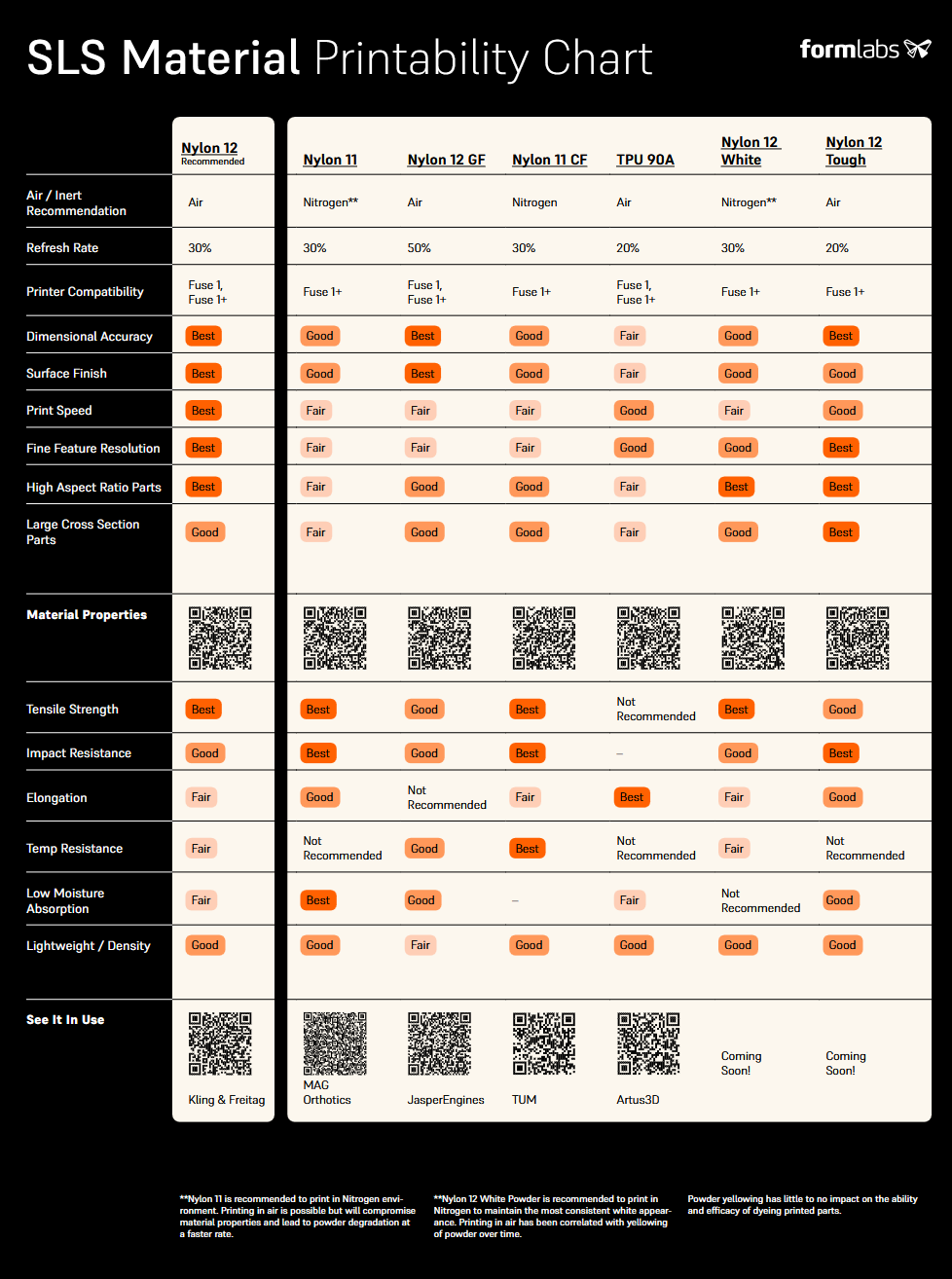

Selective laser sintering(SLS) uses powdered thermoplastics to create its models. They currently have 7(?) materials products for it, which I think primarily consists of nylon and its composites, and TPU.

The high level overview of the printing process: it lays an even, thin surface of the powder, pre heat the powder bed to just below the melting point temperature of the powder material and then, to sinter the cross-section of the model, fuse the polymer particles together by heating the particles with a laser to or near their melting point temperatures so that the particles partially melt around the surface, and then are able to fuse together. As for the preheat, I think it's done so that we can sinter easier. If we raise the initial temperature of the powder, the amount of energy needed on the laser to make the powder temperature near the sintering temperature(near Tm). Although what I don't fully understand is why we would want the laser to use less energy. Is the time to preheat the bed shorter than the time it would take if I had to apply more energy with the laser to reach Tm? I guess the tradeoff is well worth it.

Q = mcΔT, where ΔT = Tsinter − Tinitial

The big benefit of this system is that the unsintered powder plays the role of the support structure, whereas SLA and FDM you need a support. This enables the creation of more complex geometries(?). Then there is the cooling and post-processing steps. So essentially, the SLS products provide a full streamlined ecosystem for customers. From materials, to the software and hardware. This intersection is where I think I would enjoy the most, if I could become a LITTLE more technical. I saw and read that the post-processing part of the ecosystem provides 80% less labor for post processing. Does this mean time required on this step? Or like literally less labor? Either way pretty cool.

What first project would I want to work on?

Try working inversely. What use cases am I interested in? What materials do they deploy? In the application process they asked what my ideal first project would be. I've never seen this in a job application and it piqued my curiousity. After finding out how the sls printing process works and that the unsintered powders play the support structure when building, I was questioning what happens to the leftover, unused powder. Turns out you can reuse them, by mixing them with the newer powder, called refreshed rates(mixture ratio of new powder/ reused powder). I noticed that the refreshed rates are selected based on the material. What if it was more dynamic so that it reflects the actual characteristics of the status of the powder in use? But then how would this interact with the software, what about the hardware to retrieve this data?

Is it worth the time pursuing research such that it drives the costs of these expensive powders down than to put in research and resources so you can provide customers with a predictive refresh rate model that is based on the real status of the powder so that they can have better clarity and insight so to efficiently optimize the refresh rate based on their needs? I don't know.

I think I saw somewhere that Formlabs is targeting more of application specific side, which I'm guessing means that more variations of powders and resins will be available in the near future to target niche applications that may want specific characteristics.

Micronics

Then there is also the materials development that is probably going along for their new acquisition. When will they launch? And will this new model launch with a different set of materials that adheres to its strengths? I looked into Micronics, and saw that the big catch was that the estimated price of the sls printer was far lower than what exists in the industry. ~$5000 price point(or so stated) in comparison to the $20000+? This price point can enable the hobbyist sector to be fused with this sector of 3D printing. Great acquisition of a potential disruptor in the space. I am assuming that there is probably some sort of materials development going on in relation to this, which is interesting.

Final thoughts

Innovation in technology helps the world become more prosperous, although the ripple effects of it does take some time to take place. This has been happening ever since the industrial revolution, and I think that 3D printing technology is well on its way on becoming a integral part of the world.

And when I ask myself what drives innovation, I often think about earlier stage companies that are in their growth stages, where they have to prototype and iterate quite often. Based on what I've been reading and watching over the past 2-3 days, Formlabs products, especially SLS, can enable these companies to move at a faster pace all whilst being more cost efficient in certain applications.

Resources:

Why 3D printing is vital to success of US manufacturing | FT Film

Manufacturing in America, post-globalisation| FT Film

Formlabs sources: What is selective laser sintering

Choosing the right powder Fuse-1

Formlabs Whitepapers

Effect of PA12 powder recycling on properties of SLS 3D printed parts including their hygroscopicity

A review of aging, degradation, and reusability of PA12 powders in selective laser sintering additive manufacturing, limited access